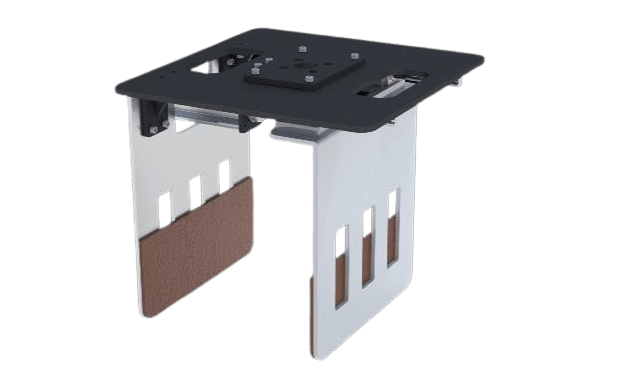

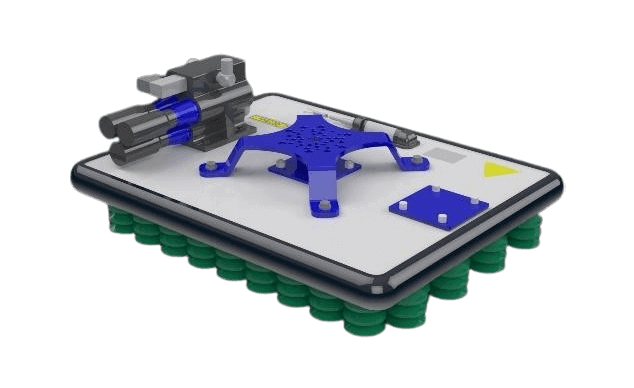

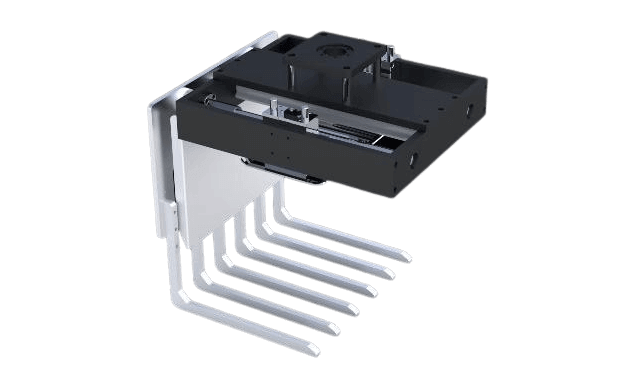

Our Gantry Palletizers are designed to meet the modern production environments where space is a constraint and the needed for the future

expansion is a consideration. Our Gantry Palletizer provides automatic palletization of cases, bags, pails and drums from one or more packaging

lines. Products are oriented consistently onto the pallet. Our modular design utilizes state of the art controls and is available from two to four

axes motion to accurately and efficiently position all product containers.

WHY USE AUTOMATIC PALLETIZING MACHINERY ?

Using an automatic palletizer offers numerous advantages that can significantly enhance the efficiency and effectiveness of industrial operations. One of

the primary reasons to employ automatic palletizers is the substantial boost in productivity they provide. Unlike manual labor, which is subject to fatigue,

errors, and varying levels of performance, automated systems can operate continuously at a consistent pace. This enables businesses to handle larger

volumes of products with greater speed, thereby meeting higher production demands without the need for additional labor.

Another critical benefit of automatic palletizers is their precision and consistency. Manual palletization can lead to inconsistencies in stacking patterns,

which can compromise the stability of pallets during transportation. Automatic systems, on the other hand, are programmed to follow exact specifications,

ensuring that each pallet is stacked uniformly. This reduces the risk of product damage during transit and helps maintain quality control standards

Cost reduction is also a significant factor in favor of automatic palletizers. While the initial investment in automation technology can be substantial, the

long-term savings are considerable. Automated systems reduce the dependency on manual labor, which can be costly and prone to human error. Over

time, this leads to lower operational costs, as businesses can allocate human resources to more skilled tasks that add greater value to the production

process.

In addition, automatic palletizers are highly adaptable to various production needs. They can be programmed to handle different types of products, pallet

sizes, and stacking patterns, making them versatile tools for businesses with diverse product lines. This adaptability also means that companies can easily

scale their operations up or down in response to changing market demands, ensuring they remain competitive.

Lastly, in a global marketplace where efficiency and speed are critical, automatic palletizers help companies meet tight deadlines and customer

expectations. By streamlining the palletizing process, businesses can improve their overall supply chain efficiency, leading to faster delivery times and

higher customer satisfaction.